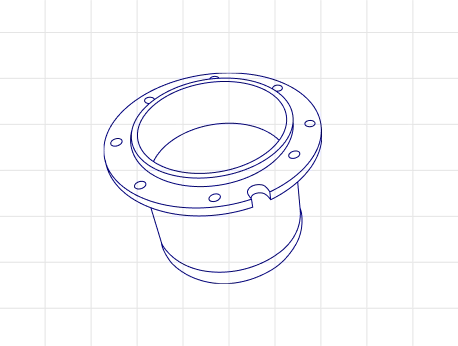

Design & Engineering Services

Kent Machine works alongside customers on the front end to ensure every concept is practical, cost-effective, and ready for manufacturing. By focusing on manufacturability from the start. Kent Machine helps reduce rework, shorten lead times, and deliver parts and fixtures that perform as intended.

What Kent Machine Delivers in Design & Engineering Services

Kent Machine supports both new designs and improvements to existing solutions, including:

- Front-end collaboration

- Design for manufacturability (DFM)

- Design optimization

- Reverse engineering

- 3+ decades of design expertise

Equipment & Capabilities

Kent Machine brings engineering expertise to every project:

- Design of custom gauges, fixtures, and work-holding systems.

- Tolerancing and GD&T support (±0.0001”).

- CAD models and drawings for customer approval.

- Early involvement to reduce cost and risk.

Industries That Count on Kent Machine

Our CNC machining is applied in sectors where precision and certification are essential:

Medical

Aerospace

Defense

Industrial

Nuclear

Automotive

Additional Processes That Pair Well with CNC Machining

CNC machining is often one step in a larger solution. Kent Machine also provides:

CNC Machining

Prototypes, low-volume, and high-volume production.

Design & Engineering

Subassemblies and certified builds.

Testing & Inspection

ISO 17025:2017 accredited and fully traceable.

Get Design & Engineering Services that optimize performance and precision.