Wire EDM

Kent Machine utilizes Wire EDM to provide solutions for intricate geometries, hardened materials, and critical applications. This method ensures precise cutting for shapes and materials that traditional machining cannot handle.

What Kent Machine Delivers in Wire EDM

Kent Machine provides custom Wire EDM services for parts and features that demand extreme precision.

- Complex part geometries

- Tight-tolerance down to ±0.0001”

- Processing of hardened steels, specialty alloys, and other conductive metals

Equipment & Capabilities

Wire EDM enables intricate cuts in tough materials with extreme precision.

- Work envelope: 14″ × 9″ × 8.75″.

- Wire diameter: as small as 0.002”.

- Tolerances to ±0.0002”.

- Processes hardened steels, alloys, and small intricate features.

Industries That Count on Kent Machine

Custom Wire EDM is used where accuracy and material performance are critical:

Medical

Aerospace

Defense

Industrial

Nuclear

Automotive

Additional Processes That Pair Well with Wire EDM

EDM often works alongside Kent Machine’s other capabilities.

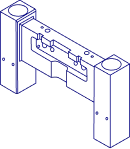

CNC Machining

Machined parts with EDM features added

Complex Gauges

EDM precision applied to gauge components

Work-Holding Fixtures

EDM-cut elements for fixture accuracy

Design & Engineering

CAD and GD&T support for manufacturable designs

Testing & Inspection

ISO 17025 traceable verification

Request Custom Wire EDM services for the complex shapes and materials you need cut with precision.