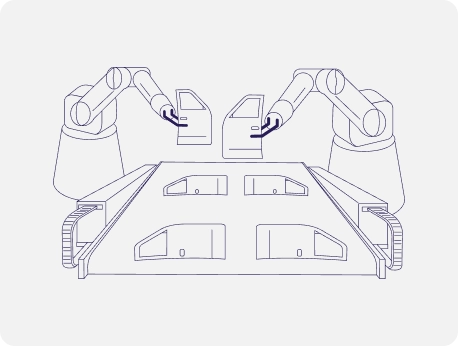

Assembly Equipment

Kent Machine specializes in designing and building assembly equipment that streamlines production, reduces manual errors, and enhances efficiency. Kent Machine solutions ensure consistency, improve ergonomics, and integrate quality throughout manufacturing processes, allowing operations to proceed with confidence.

What Kent Machine Delivers in Assembly Equipment

Kent Machine develops assembly equipment tailored to customer needs.

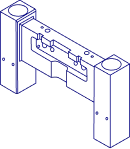

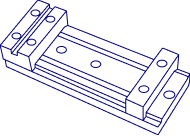

- Custom assembly fixtures and stations

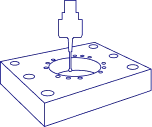

- Integration of inspection and gauging

- Ergonomic equipment

- Process validation equipment

Equipment & Capabilities

Custom assembly systems improve efficiency and ensure repeatable results.

- Custom assembly fixtures, stations, and full systems.

- Integration of gauging and inspection.

- Mechanical, electrical, pneumatic, robotic capabilities.

- Reduce operator error, improve ergonomics, validate processes.

Industries That Count on Kent Machine

Assembly equipment is trusted where consistency and compliance are essential.

Medical

Aerospace

Defense

Industrial

Nuclear

Automotive

Additional Services That Pair Well with Assembly Equipment

Assembly often works hand-in-hand with other Kent Machine capabilities.

CNC Machining

Precision parts built for integration into assemblies

Complex Gauges

Measurement tools built into assembly systems

Work-Holding Fixtures

Secure setups for consistent assembly steps

Design & Engineering

CAD and GD&T support for optimized equipment

Testing & Inspection

Verification that assemblies meet performance standards

Secure Complex Gauges designed for accuracy, compliance, and repeatable measurement.