Kent’s custom manufacturing services

Kent can take full ownership of your project’s success because we offer comprehensive custom manufacturing services.

Whether you have fully refined designs ready for manufacturing or a tough problem in need of a custom solution, Kent will deliver what you need on your terms.

No excuses. No delays. Just exceptional custom manufacturing services.

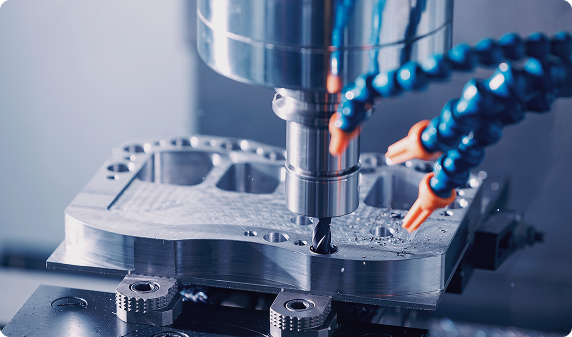

CNC Machining

Kent is a full-service CNC machining shop specializing in complex parts.

Whether you’re looking for a one-off part or a production run, we hold tolerances of 0.0002” for low volume production.

As a machine shop with an ISO 17025 accredited laboratory, we deliver the consistent quality you can depend on, regardless of your job’s complexity.

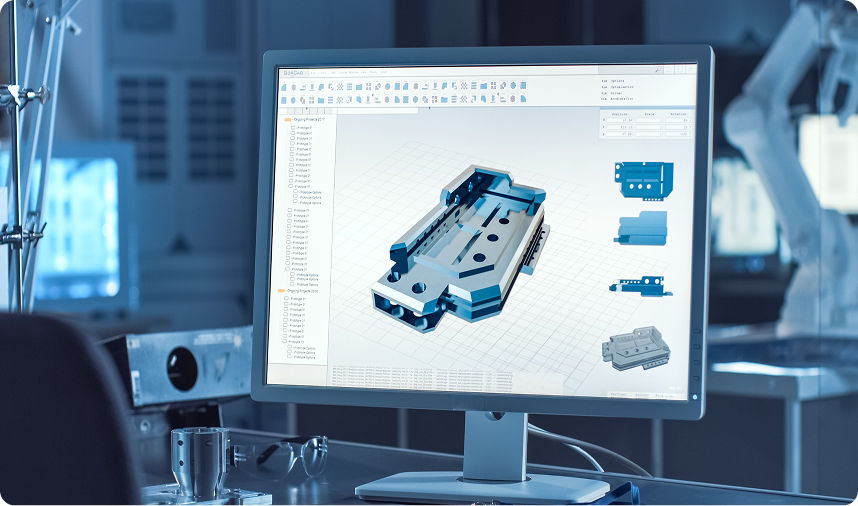

Design & Engineering

The Kent team brings decades of combined experience to every design and engineering challenge.

Got a design you want to optimize to boost performance and reduce costs? We can do that.

Got a part you need reverse engineered? No problem.

Got a vision you’re looking to turn into a practicable design? We can do that, too.

We design:

- Fixtures

- Gauges

- Jigs

- Tooling

Prototyping

Staying competitive requires a prototyping process that identifies all manufacturing and performance challenges as early as possible.

That’s why Kent’s prototyping process is designed to help companies stay agile.

We leverage our expertise to identify problems—and solutions—before production, to shorten your time between concept and launch.

- Lead times: 4-6 weeks

- Maximum milling work envelope: X-axis 40″, Y-axis 40″, Z-axis 20″

- Maximum turning work envelope: 17″ swing and 48″ between centers

- Tolerance: 0.0002”

- Secondary operations:

- Heat treating

- Cryogenic freezing

Complex Gauges

Kent has been designing and maxing custom gauges since our founding. It’s our bread and butter.

We make:

- Profile gauges

- Fixture gauges

- Chamfer gauges

- Depth gauges

Need a custom gauge? Tell us what you need, and we’ll make it happen.

- Lead times: 4-6 weeks for build to print, 8-12 weeks for design and build

- Max part size: 40” x 50”

- Tolerance: 0.0001” size, 0.0002” profile

- Secondary operations:

- Heat treating

- Cryogenic freezing

- Grinding

- Calibration

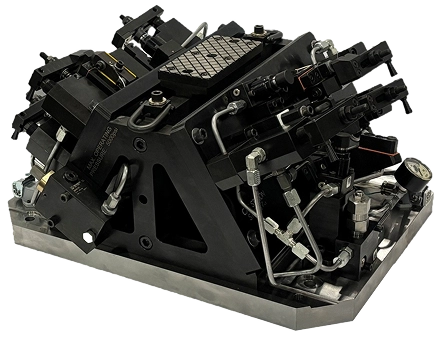

Work-Holding Fixtures

Need manual or automatic load fixtures? We can make that.

Looking for manual, pneumatic, or hydraulic clamping? No trouble.

Whether you’re looking for light curtains or communication with your machine, Kent can design and build a custom fixture that will meet your requirements.

Our hydraulic integration capabilities include both internal and external porting. All fixtures are designed to conform to ANSI 14.5 GD & T standards.

- Lead times: 4-6 weeks for build to print, 8-12 weeks for design and build

- Types of integration:

- Electrical

- Hydraulic (internal & external)

- Pneumatic

- Secondary operations

- Heat treating

- Cryogenic freezing

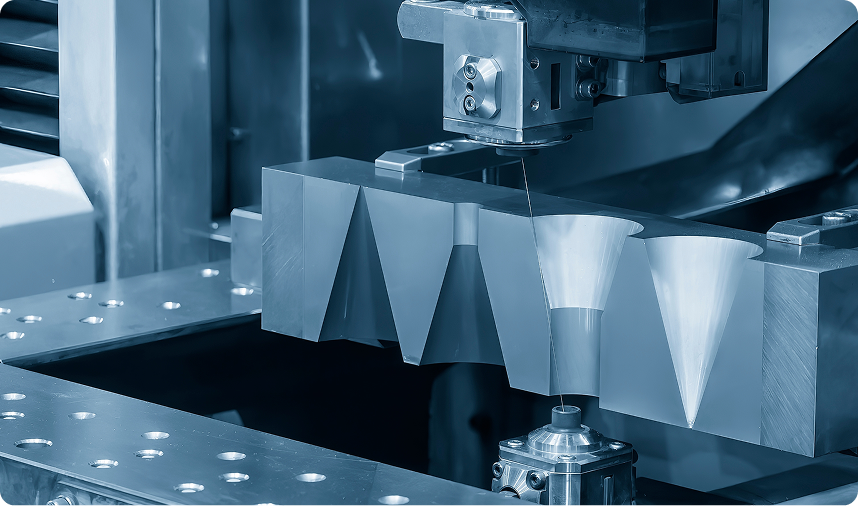

Custom Wire EDM

Kent offers custom fabrication of complicated profiles in wire as thin as 0.002” in diameter.

And thanks to our ISO 17025:2017 accredited lab, you can rest assured you get the quality you need every time.

- Lead time: 4-6 weeks

- Maximum work envelope: X-axis 14″, Y-axis 9″, Z-axis 8.75″

- Minimum wire diameter: 0.002”

- Tolerance: 0.0002”

Quality Inspection & Testing

If you’re making high-performance products, you can’t leave anything to chance.

For decades, we’ve specialized in making custom test & inspection machines designed for your unique manufacturing processes.

And thanks to our own rigorous quality control process, you can be sure your part will always meet the standards of medical, aerospace, and other exacting industries.