Quality Inspection & Testing

Kent Machine provides quality assurance services that confirm every part, gauge, or fixture performs as designed. Kent Machine delivers the documented proof manufacturers need to meet the strictest standards.

What Kent Machine Delivers in Quality Inspection & Testing

Kent Machine’s inspection and testing services give manufacturers confidence in their quality.

- ISO 17025:2017 accredited inspection.

- Calibration and recertification

- Measurement of complex geometries

- Troubleshooting quality issues

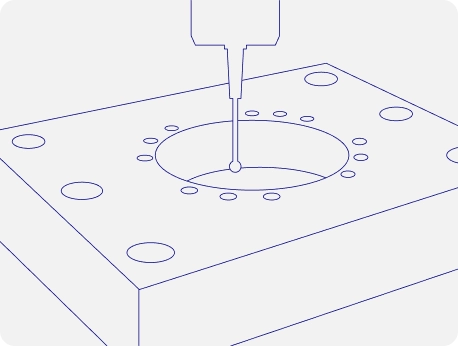

Equipment & Capabilities

Inspection services confirm part quality and provide certified documentation.

- First-article, calibration, recertification, dimensional checks.

- Handling of tight tolerances and compound geometries.

- Development of custom test & inspection machines

Industries That Count on Kent Machine

Quality inspection and testing services are trusted where compliance and certification are critical.

Medical

Aerospace

Defense

Industrial

Nuclear

Automotive

Additional Processes That Pair Well with Quality Inspection & Testing

Inspection often works alongside Kent Machine’s other services for full assurance.

CNC Machining

Parts inspected before delivery

Gauges & Fixtures

Calibrated and certified for accuracy

Work-Holding Fixtures

Verified for repeatability

Design & Engineering

Models validated against measured results

Assembly

Builds delivered with inspection reports

Ensure compliance—start Quality Inspection and Testing services with Kent Machine.