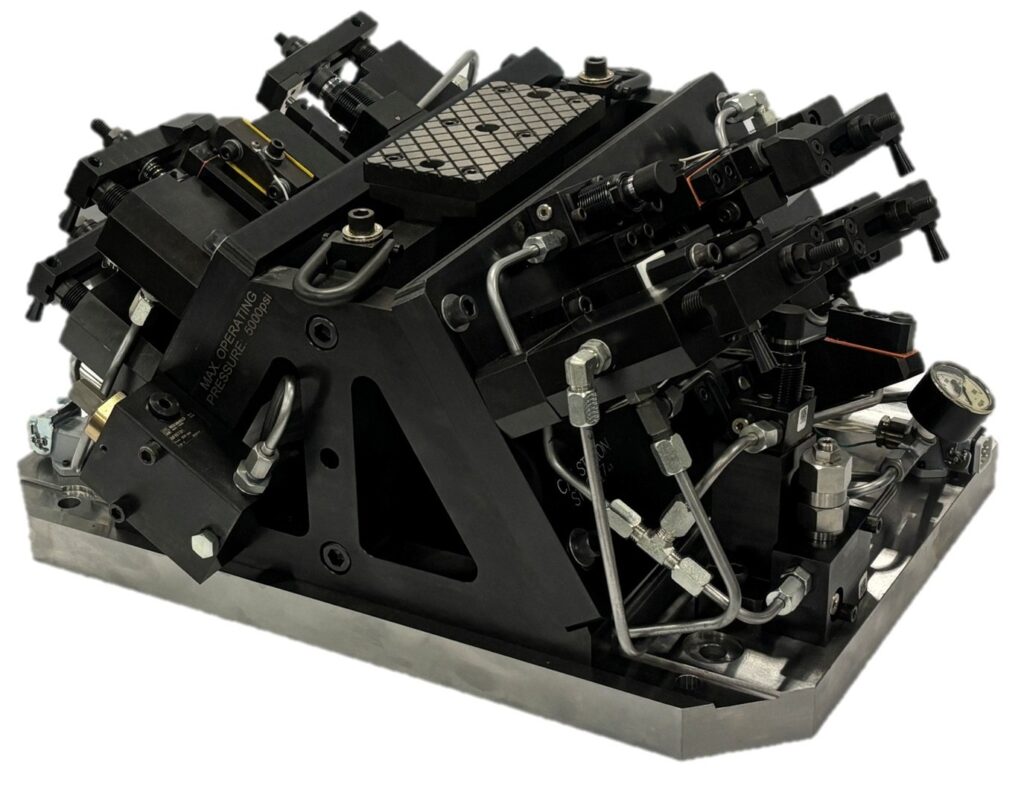

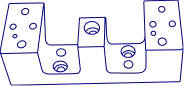

Work-Holding Fixtures

Kent Machine builds work-holding fixtures that bring stability and repeatability to every operation. Designed to keep parts secure and consistent, these fixtures streamline production, reduce errors, and maximize efficiency across machining and inspection processes.

What Kent Machine Delivers in Work-Holding Fixtures

Kent Machine builds fixtures that are designed to keep parts stable and processes consistent with:

- Complex part geometries

- CNC and gauge integration

- Clamping to ±0.0001"

Equipment & Capabilities

Fixtures are engineered to secure complex parts for accurate machining and inspection.

- Manual, pneumatic, and hydraulic clamping systems.

- Fixtures designed to ANSI Y14.5 GD&T.

- Securement of complex geometries for machining/inspection.

- Scrap and variation reduction.

Industries That Count on Kent Machine

Trusted in industries where accuracy and repeatability are critical:

Medical

Aerospace

Defense

Industrial

Nuclear

Automotive

Additional Processes That Pair Well with Work-Holding Fixtures

Fixtures often complement Kent Machine’s other capabilities.

CNC Machining

Fixtures designed to support cutting operations.

Complex Gauges

Paired with gauges to confirm part accuracy.

Design & Engineering

Models and GD&T for exact fit.

Assembly

Delivered within certified subassemblies.

Testing & Inspection

ISO 17025 verification for reliability.

Get custom Work-Holding Fixtures that keep parts secure and processes consistent.