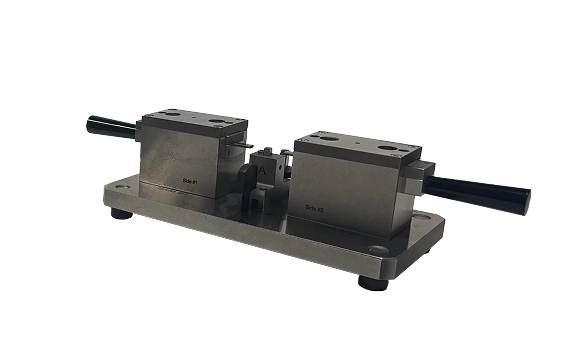

Complex Gauges

Kent Machine designs and builds complex gauges that provide measurement certainty and compliance. From profile to taper designs, each gauge is accurate, repeatable, and fully certified for critical applications

What Kent Machine Delivers in Complex Gauges

Kent Machine supports customers through the complete lifecycle of gauge design and delivery.

- Tolerances down to ±0.0001"

- ISO 17025:2017 accredited inspection

- Custom designs

- Traceable documentation for regulatory compliance

Equipment & Capabilities

Kent Machine designs and certifies gauges that deliver precise, repeatable measurement.

- Profile, fixture, chamfer, flush pin, taper, and custom gauges.

- Tolerances: ±0.0001” size, ±0.0002” profile.

- ISO 17025 calibration and traceability.

- Integration with fixtures and production.

Industries That Count on Kent Machine

Kent Machine’s gauges are used where measurement certainty matters most:

Medical

Aerospace

Defense

Industrial

Nuclear

Automotive

Additional Processes That Pair Well with Complex Gauges

CNC machining is often one step in a larger solution. Kent Machine also provides:

CNC Machining

Tight-tolerance parts and components.

Design & Engineering

CAD models, GD&T, and design refinement.

Work-Holding Fixtures

Custom systems that integrate into production.

Assembly

Certified builds and subassemblies.

Testing & Inspection

Accredited, traceable verification.

Secure Complex Gauges designed for accuracy, compliance, and repeatable measurement.