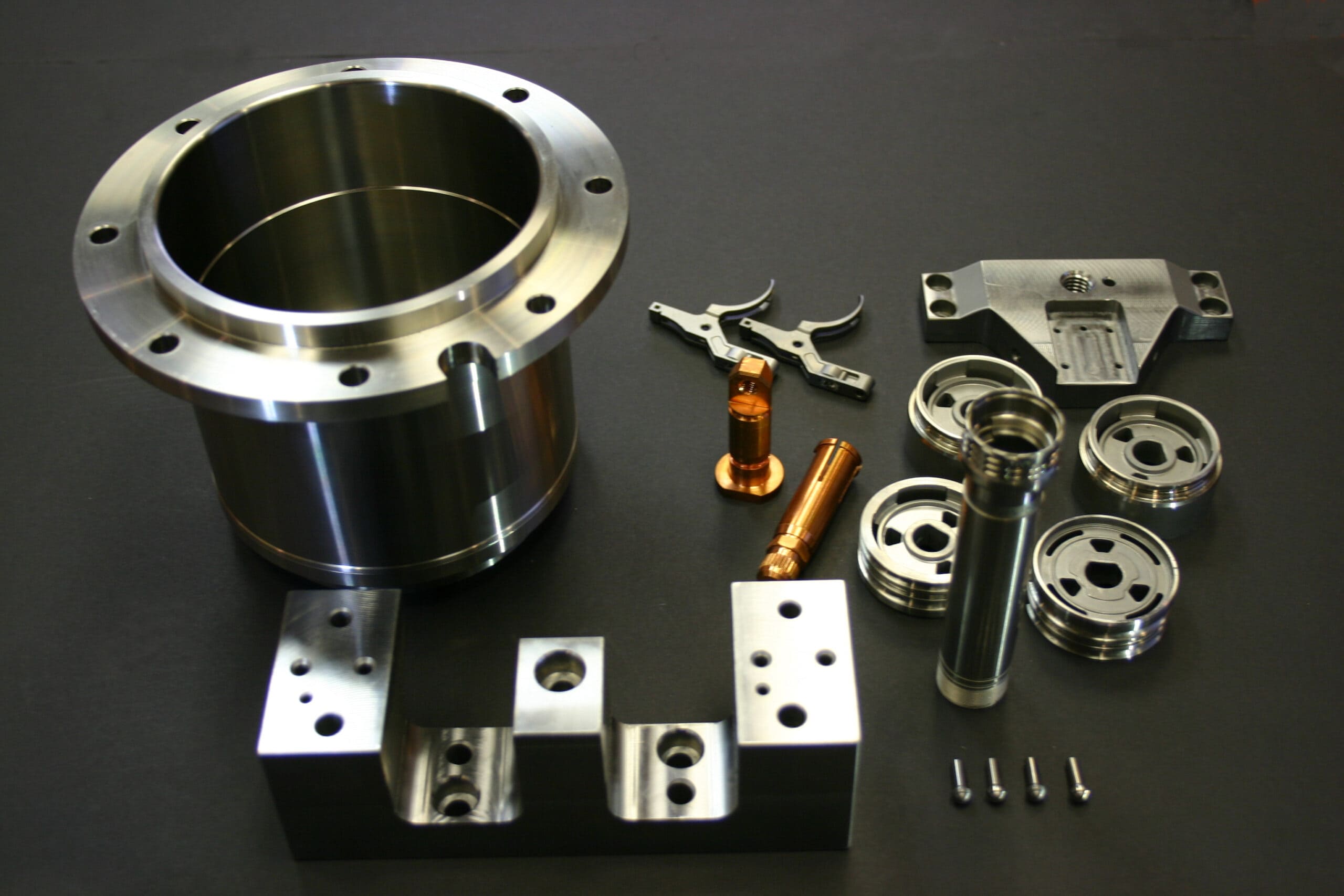

Prototype to Production Volume Machining

(click on thumbnail to enlarge)

Kent Machine offers prototype to production volume milling, turning, and grinding services. We also offer medium to high volume Swiss turning.

Producing components from hardened steel, stainless, exotic aerospace materials, plastic, or non-ferrous materials according to your most stringent requirements is no problem for us. Most machined components can be easily machined to tolerances of ± 0.0002″ (steel). Dimensional accuracy of your components is verified in our ISO 17025:2017 certified laboratory. Our team has experience working with components that require multiple processes including heat treating, plating and coatings and various non-destructive and destructive tests.

For components that do not require certified heat treating, we offer our in-house heat treatment services, which reduces our turnaround time. We also offer cryogenic freezing services using our in-house liquid nitrogen bath for the production of stable, stress free, components.

For additional information or for your personal consultation regarding your component or product please select the “RFI” request information selection button to begin your communication.

Specifications

- Lead Times

-

At Kent Machine our typical lead time is 4-6 weeks. Contact us for a delivery quote for your specific project.

- Maximum Milling Work Envelope

-

X-axis 40″, Y-axis 40″, Z-axis 20″

- Maximum Turning Work Envelope

-

17″ Swing and 48″ Between Centers

- Tolerances

-

to +/- 0.0002″

- Product Categories

-

Custom Molded Urethane Components

Grippers

Locating Nest components

Locator Blocks

Locator Pins

Special Chuck JawsPrecision Machined Parts

- Secondary Operations

-

Heat Treating

Cryogenic Freeze (Microstructure Stress Relieve)

Capabilities

- Equipment List

-

Equipment List (PDF – 47KB)

Equipment List (PDF – 47KB)

- Specialty Capabilities

-

Kent Machine has in-house specialty Heat Treating and Cryogenic Freeze capabilities to insure the quickest turnaround, highest quality, and dimensional consistency for your gauging and checking equipment needs. Our on-site Cryogenic Freeze cycle in (-270°F) Liquid Nitrogen (HT>Draw>Freeze>Draw) stabilizes and stress relieves the material’s molecular structure for maintaining dimensional consistency during the final grinding process, likewise assuring only the tightest tolerances and finest surface finishes for the most precise gauges and inspection fixtures.

Examples

- Precision Components

-

Specialized blueprint components are maintained to tolerances of 0.0002″. Virtually any material is a candidate for components for special machines that require a unique wear surface.

larger image

Other Information

- Acceptable Drawing Formats

-

- Solidworks

- Parasolids

- STP / STEP

- Inventor

- Solid Edge

- CATIA (*.cgr)

- ProE / Creo

- Unigraphics / NX

- Rhino (*.3dm)

- AutoCAD

- Certifications

-

- ISO 17025 Certification and Scope

- Industries Served

-

- Aerospace

- Orthopedic Implants

- Medical Instrumentation

- Automotive Components and Castings

- Advantages

-

Kent Machine is a one-stop, quick-turnaround shop for gauge, machine and fixture design, build and calibration. We design, fabricate, build, calibrate and test our custom gauges and inspection equipment so you can confidently use them in production immediately upon receipt of your order.